|

DOI: 10.7256/2453-8809.2017.2.23150

Received:

29-05-2017

Published:

17-06-2017

Abstract:

The research object is the process of functioning of the excavating parts of a cultivating separating ripper, which transforms the structure and the density of a soil layer in accordance with the requirements of agronomical science for the cultivated crop. This result is achieved using the coordinated interaction of passive and active excavating parts. The machine also combs out the weed. The author considers the plowshare with steering disks, which spends less energy when moving through soil and directs soil to the separator. Theoretical researches are based on mechanical and mathematical modeling of interaction of the moving parts with soil. Experimental researches are based on the sectoral methods using strain-gage instruments and the methods of multifactor experiments planning. In the result, the process of soil cultivation using disk cultivating parts has been improved, the theory of justification of the parameters of active-passive cultivating parts for the separation and pulverization of soil and been developed; the mathematic model of interaction of cultivating parts with soil with account of energy intensity rates of technological processes has been composed. The use of methods of direct variational calculation for the justification of shapes of cultivating parts of a cultivating separating ripper helps reduce energy consumption by 10-30%.

Keywords:

movement through soil, shape of a plowshare, cultivating parts, separation, cultivating separating ripper, real tillage, secondary tillage, tillage with separation, steering disks, building-up

This article written in Russian. You can find original text of the article here

.

Введение. Механическая обработка почвы является одним из самых весомых факторов, который в дальнейшем определяет способность почвы обеспечить растения водой, воздухом, теплом и питательными веществами. Кроме того, при обработке почвы, уничтожаются сорные растения и вредители, заделываются в нее растительные остатки и удобрения. Высококачественное выполнение этих операций во многом влияет на дальнейшее наращивание плодородия почвы или, как минимум, поддержание его на должном уровне взамен используемых культурными растениями всех питательных веществ во время выращивания.

Поэтому возникла необходимость создания принципиально новых почвообрабатывающих машин и орудий, новых способов обработки почвы. Последнее, возможно путем сокращения или совмещения технологических операций, уменьшением глубины обработки и т.д., что входит в технологию так называемых «минимальных» и «нулевых» обработок почвы [1,2].

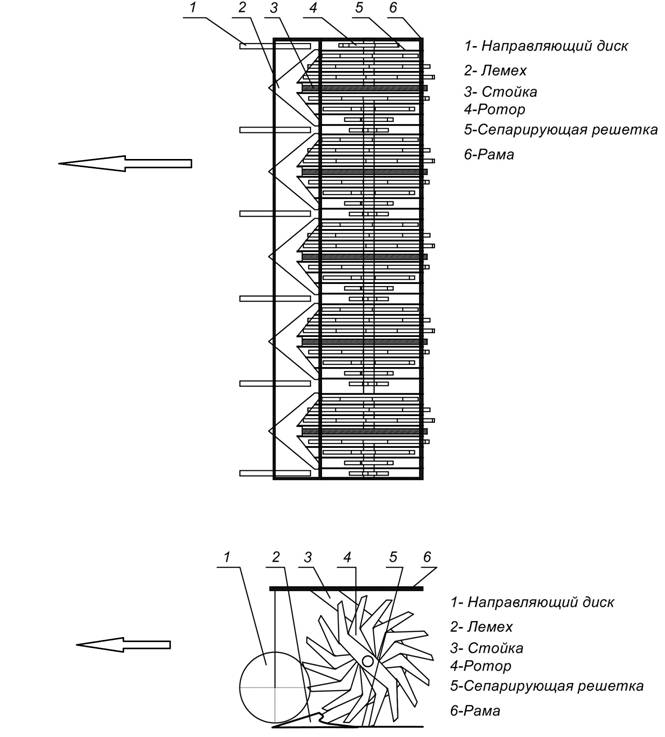

Постановка задачи. Известная рыхлительно-сепарирующая машина для предпосевной обработки почвы [3] состоит из рабочих органов для подъема почвы и рыхлительно-сепарирующего устройства (рис. 1).

Рис. 1. Принципиальная схема почвообрабатывающей рыхлительно-сепарирующей машины.

При движении машины, установленные на раме свободновращающиеся диски внедряются в почву и перекатываются в ней, при перемещении своей оси в направлении, вращения ротора. Вращательным движением диски, способствуют отрыву почвы, поджатой между ними, от массива, и далее движению ее по лемеху. Подъем почвы необходим для подачи ее на лемех и далее выполнения процесса фракционного перераспределения комочков почвы. Расстояние между дисками подобрано таким образом, чтобы почва между ними не заклинивалась. Последнее исключает излишний подъем почвы, отрыв ее от поверхности лемеха и нарушение технологического процесса работы устройства для подъема почвы. При этом возникает необходимость в выборе профильной линии лемеха таким образом, чтобы затраты энергии на перемещение его в почве были минимальными.

Анализ исследований и публикаций. Структурный состав почвы во многом зависит от наличия и оптимального сочетания в ней твердой, жидкой и газообразной фаз. Опыты, проведенные учеными Э. Вольни, В.В. Квасниковым, М.М. Голдиным и другими указывают на то, что более высокие урожаи сельскохозяйственных культур были получены на хорошо оструктуренных почвах [4].

Учеными проведено большое количество исследований, направленных на снижение энергоемкости обработки почвы, но результаты исследований не были широко внедрены в практику из-за несовершенства конструкций предлагаемых устройств [5].

Современная наука все шире рекомендует производству применение минимальной почвозащитной системы обработки почвы путём уменьшения глубины обработки, количества механических обработок или объединение ряда технологических операций [6]. Такой технологией достигается сохранение структуры почвы, устраняется чрезмерное уплотнение почвы, повышается её стойкость против эрозионных процессов [7]. В степной зоне хорошо зарекомендовала себя система мелкой обработки почвы под озимые культуры, которые размещаются после непаровых предшественников, или по занятому пару.

Идеи уменьшения количества выполняемых операций в земледелии давно выдвигаются учеными. Ещё Д.И. Менделеев писал, что «…относительно качества пахоты многие ошибаются, думая, что чем больше раз пахать, то тем лучше».

Существует много способов минимизации обработки почвы, но все основные мероприятия сводятся к следующему:

– использование гербицидов;

– применение широкозахватных агрегатов;

– применение комбинированных агрегатов;

– фрезерование почвы.

Так называемая «нулевая» обработка почвы предполагает обработку гербицидами междурядий, а в зоне заделки семян проводится рыхление почвы.

Из перечисленных способов минимизации обработки почвы приоритетное направление все больше набирает применение комбинированных почвообратывающих машин и агрегатов [8, 9, 10]. Последние имеют высокую производительность, дешевые в использовании, не нарушают агротехнических требований и способствуют снижению сроков выполнения технологических операций. Разделяют три основные типы комбинированных машин и агрегатов:

– агрегат комплектуется из нескольких, последовательно соединенных простых машин, каждая из которых выполняет свою операцию;

– последовательно устанавливаются на одной раме различные рабочие органы для выполнения технологического процесса;

– машины со специальными комбинированными рабочими органами.

Широкое распространение получили комбинированные почвообрабатывающие машины типа «Европак», к рабочим органам которых относятся выравниватели, S-образные лапы и ротационные измельчители комков. Использование данных машин в производстве позволяет объединить от двух до шести операций и снизить на 20…40 % расход топлива на предпосевную подготовку почвы.

Агрегаты, составленные на основе комбинации однооперационных орудий, хотя и имеют некоторые преимущества, не оправдывают себя из-за своей громоздкости, неустойчивости движения в прямолинейном направлении и несоответствия их ширины захвата. Посевные комбайны, с установленными на одной раме рабочими органами сеялки и почвообрабатывающих орудий, выполненные в виде лап или дисков, менее громоздки.

Применение на комбинированных машинах активных рабочих органов позволяет за один проход агрегата обеспечить высокое качество обработки почвы. Такие машины, как правило, состоят из фрез и рабочих органов сеялки [11, 12]. Однако широкого распространения машины с активными рабочими органами не получили из-за большой энергоемкости и ненадежности в работе. Последнее объясняется большими затратами энергии на отбрасывание почвы фрезами, которые в общих затратах энергии составляют от 30 до 70 %.

По назначению комбинированные машины можно разделить на три группы. Первая группа – машины для совмещения основной и предпосевной обработки почвы. К этой группе можно отнести комбинированные агрегаты и машины: ГРН-1,6; ГРН-3,9; агрегат «Смарагд» фирмы «Лемкен»; «Европак»; АПЧ-2,5; АКШ-3,6; RAY-Polu AG; АКП-2,5; АКП-5; комбинированная машина АКР-3,5; АГРО-3 и др.

В разных вариантах использование машины АГРО-3 позволило получить агрономически ценных комков (0,25…10 мм) в верхнем слое почвы 62,5 %.

Исследуемые образцы обработки чизельным рыхлением также дают лучшие показатели, в сравнении с 2-х разовым дискованием БДТ-7. При чизельном рыхлении их было 84 шт./м2 против 92 шт./м2 при 2-разовом дисковании БДТ-7.

Вторая группа машин для совмещения операций предпосевной обработки почвы включает комбинированные машины РВК-3,6; РВК-5,4; РВК-7,2, выравниватель ВИП-5,6, культиватор-глубокорыхлитель КФГ-3,6, грядкообразователь УГН-4К, комбинированные агрегаты RAU-STERNILLER, PAY-TERRAMAKC, АПБ-6, «Копактор», ККП-6, КНШ-6, «Резидент», «Система-Коруну» и другие.

Третья группа – машины для совмещения предпосевной обработки почвы и сева. Эти машины выполняют предпосевную культивацию и посев. В большинстве случаев в эту группу входят простые машины (культиватор и сеялка), а также специальные почвообрабатывающие и посевные агрегаты, такие как фрезерные культиваторы-сеялки, сеялки-культиваторы, лущильники-сеялки, фрезерные культиваторы, сеялки и комбинированный агрегат КА-3,6; АПП-6, «Солитер» фирмы «Лемкен» и другие.

Рассмотренные машины позволяют сократить время на подготовку к той или иной операции, что дает преимущества над теми машинами, которые использовались в сельском хозяйстве до этого времени. Сокращение количества выполняемых операций способствует снижению затрат на предпосевную обработку почвы по сравнению с общепринятой технологией на 52 %, а затраты горюче-смазочных материалов – на 47,8 %.

Анализ работы различных типов почвообрабатывающих комбинированных машин показал, что наибольшую перспективу имеют машины, которые за один проход выполняют весь комплекс работ по подготовке почвы к посеву. Такие комбинированные машины позволяют сократить до минимума сроки выполнения технологических операций, расход энергии и средств на их выполнение.

Производственные испытания предлагаемого типа комбинированных машин показывают, что лучшие показатели в работе дает тип комбинированных машин, оборудованных специальными рабочими органами для последовательного выполнения технологического процесса подготовки почвы к посеву, связанных с выращиванием сельскохозяйственных культур.

Менее энергоёмкими и более надёжными в работе являются комбинированные почвообрабатывающие машины с активно-пассивными рабочими органами. К таким относится машина почвообрабатывающая рыхлительно-сепарирующая «Докучаевская» ПРСМ-5 стратификатор (Рис. 2).

Рис. 2. Экспериментальная почвообрабатывающая рыхлительно-сепарирующая машина в агрегате с трактором ХТЗ-17221

Работает машина следующим образом, Лапа подрезает пласт почвы снизу и подает его к рыхлительно-сепарирующему устройству. Ножи ротора захватывают почву, перемещают ее по сепарирующей решетке с одновременным ее крошением. При ворошении почвы на сепарирующей решетке ножами ротора крупные ее частицы и корневища растений выталкиваются на поверхность, мелкие – просыпаются вниз.

Для того, чтобы почва не сгруживалась и не рассыпалась в стороны, с обеих сторон лемеха были установлены пассивные вращающиеся диски.

В данном случае плоские свободновращающихся диски работают как дополнительный рабочий орган.

При движении машины (рис. 1), установленные на раме свободновращающиеся диски внедряются в почву и перекатываются в ней, при перемещении своей оси в направлении, вращения ротора. Вращательным движением диски 1, способствуют отрыву почвы, поджатой между ними, от массива, и далее движению ее по лемеху. Одновременно установленная на стойке закрепленной на раме 6, стрельчатая лапа (лемех) 2, обеспечивает их заглубление, подъем слоя почвы оторванной от массива плоскими свободновращающимися дисками 1 , которая поднимаясь, частично крошится, движется, попадая на сепарирующую решетку 5. Также направляющие диски 1 ограничивают сгруживание почвы с лемеха на стороны [3].

Из вышеизложенного следует, что такие рабочие органы комбинированной почвообрабатывающей машины обеспечивают высокое качество обработки почвы с одновременным снижением энергоемкости ее проведения. В связи с этим и возникла необходимость в дальнейшем исследовании процесса функционирования рабочих органов данной почвообрабатывающей рыхлительно-сепарирующей машины для их применения в различных вариантах использования в технологиях механизированной обработки почвы.

Цель статьи. Обосновать профиль лемеха с направляющими дисками с минимальными затратами энергии на его перемещение в почве.

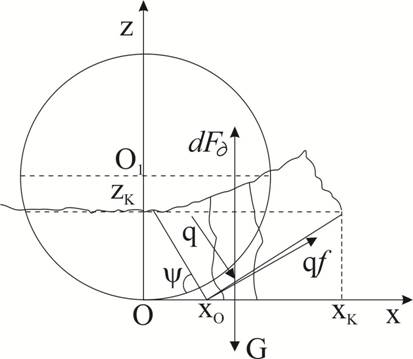

Основной материал. При решении задачи будем полагать, что рыхлительно-сепарирующая машина перемещается прямолинейно с равномерной скоростью, диски вращаются по отношению к движущейся по лемеху почве, не изменяя траектории движения ее частиц, а силами инерции вследствие малых скоростей можно пренебречь. На рис. 3 показана в подвижной декартовой системе координат схема рабочих органов для подъема почвы.

Рис. 3. Схема к обоснованию профильной линии

лемеха с направляющими дисками

Выделим в почве элементарный пласт, на который действует сила его веса dG и сила трения о него дисков  . На элементарный участок лемеха действует нормальное давление почвы qdl и сила трения fqdl. Силу сопротивления движению лемеха в почве определяем с учетом того, что не весь слой почвы, расположенный на лемехе, находится в зоне действия дисков. В этом случае силу сопротивления вычисляем по формуле . На элементарный участок лемеха действует нормальное давление почвы qdl и сила трения fqdl. Силу сопротивления движению лемеха в почве определяем с учетом того, что не весь слой почвы, расположенный на лемехе, находится в зоне действия дисков. В этом случае силу сопротивления вычисляем по формуле

(1) (1)

где  – нормальное давление почвы на элементарную площадку лемеха в зоне действия дисков; – нормальное давление почвы на элементарную площадку лемеха в зоне действия дисков;

– нормальное давление почвы на элементарную площадку вне зоны действия дисков; – нормальное давление почвы на элементарную площадку вне зоны действия дисков;

– координата точки, разделяющей зоны действия дисков на почву. – координата точки, разделяющей зоны действия дисков на почву.

Если предположить, что давление почвы по ширине лемеха распределяется равномерно, то сила трения дисков о почву уменьшает воздействие силы веса пласта почвы на лемех на величину, пропорциональную площади трения пласта о диски. Тогда

(2) (2)

где  – проекция на вертикальную ось элементарной силы трения дисков о почву. – проекция на вертикальную ось элементарной силы трения дисков о почву.

Сила веса элементарного пласта почвы единичной толщины определяется из уравнения

где gВ – объемный вес почвы;

h– высота слоя почвы на лемехе;

b– ширина лемеха.

Для упрощения решения задачи проекцию элементарной силы трения дисков о почву принимаем пропорциональной площади трения и вычисляем по формуле

(3) (3)

где  – коэффициент пропорциональности между площадью поверхности трения дисков о пласт почвы и проекцией силы трения; – коэффициент пропорциональности между площадью поверхности трения дисков о пласт почвы и проекцией силы трения;

– значения ординат профильной линии поверхности лемеха и режущей кромки направляющих дисков, причем – значения ординат профильной линии поверхности лемеха и режущей кромки направляющих дисков, причем

(4) (4)

Во второй зоне силы трения дисков о почву отсутствуют, поэтому

(5) (5)

С учетом уравнений (2)...(5) выражение (1) принимает вид

(6) (6)

Если учесть результаты исследований Г.Н. Синеокова и И.М. Панова [10], М.И. Мацепуро и И.В. Манюты [13] по обоснованию параметров лемеха для подъема почвы и на их основании выбирать граничные условия, то следует уточнить профиль лемеха в связи с установкой по его бокам направляющих дисков. В таком случае постановка задачи формулируется следующим образом. Среди множества кривых, проходящих через точки  и и  выбрать такую, которая описала бы профильную линию лемеха, обеспечивающего минимальное тяговое сопротивление движению в почве. выбрать такую, которая описала бы профильную линию лемеха, обеспечивающего минимальное тяговое сопротивление движению в почве.

Уравнение кривой профильной линии лемеха, удовлетворяющее граничным условиям, будем искать в виде

(7) (7)

где  – коэффициенты, подлежащие определению. – коэффициенты, подлежащие определению.

После дифференцирования уравнения (7) по x получим

(8) (8)

Определив частные производные (6) по  и приравняв их к нулю, получим следующую систему уравнений и приравняв их к нулю, получим следующую систему уравнений

(9) (9)

где

При дифференцировании выражения (6) полагаем, что координата  , разграничивающая зону действия дисков на почву, зависит только от их радиуса, глубины хода, величины сгруживания почвы на лемехе и не зависит от профиля лемеха. В противном случае необходимо было бы сначала решить задачу по определению влияния профиля лемеха на значение координаты и проводить дифференцирование выражения (6) с учетом подвижных пределов интегрирования. , разграничивающая зону действия дисков на почву, зависит только от их радиуса, глубины хода, величины сгруживания почвы на лемехе и не зависит от профиля лемеха. В противном случае необходимо было бы сначала решить задачу по определению влияния профиля лемеха на значение координаты и проводить дифференцирование выражения (6) с учетом подвижных пределов интегрирования.

Решив систему из двух уравнений (9) с двумя неизвестными  с учетом выражений (7) и (8), получим значения искомых коэффициентов. с учетом выражений (7) и (8), получим значения искомых коэффициентов.

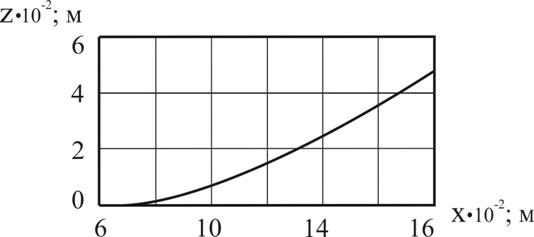

Систему уравнений (9) решаем при R= 0,18 м; X0 = 0,05 м; X1 = 0,14 м; Xk = 0,18 м; Zk = 0,05 м; f= 0,5; b=0,1 м; h= 0,1 м; KП = 2. В результате уравнение, описывающее профиль лемеха, имеет вид

(10) (10)

График полученной зависимости представлен на рис. 4.

Рис. 4. Теоритически обоснованный профиль лемеха с направляющими дисками

Эксперименты по определению тягового сопротивления лемехов с направляющими дисками с прямым и теоретически обоснованным профилем проводили в почвенном канале при глубине обработки 0,12 м и влажностью почвы 20 %. Эксперимент проводился c четырехкратной повторностью.

Скорость движения тензометрической тележки составляла 0,69 м/с. Данные о тяговом сопротивлении лемехов с направляющими дисками с прямым и теоретически обоснованным профилем приведены в табл. 1.

Таблица 1

Тяговые сопротивления лемехов, Н

|

Повторность

|

Тип лемеха

|

% к лемеху прямого

профиля

|

|

Прямого профиля

|

Экспериментального

|

|

1

|

125,0

|

89,25

|

|

|

2

|

143,0

|

75,75

|

|

|

3

|

152,0

|

89,25

|

|

|

4

|

138,5

|

89,25

|

|

|

Среднее

|

139,6

|

85,88

|

61,5

|

Результаты статистической обработки полученных экспериментальных данных с использованием критерия Фишера показывают, что доля влияния фактора составляет 91,8 %, достоверны с вероятностью 95 %. Наименьшая существенная разница составляет 22,626 Н.

Анализ данных таблицы показывает, что лемех с теоретически обоснованным профилем по сравнению с лемехом с прямым профилем имеет тяговое сопротивление на 38,5 % меньше, что подтверждает достоверность результатов теоретических исследований.

Выводы. Обоснован профиль лемеха с направляющими дисками с минимальными затратами энергии на его перемещение в почве. Результаты экспериментов подтвердили достоверность теоретических исследований по обоснованию профиля лемеха с направляющими дисками. Доказано, что лемех с направляющими дисками с обоснованным профилем, имеет тяговое сопротивление на 38 %. меньше в сравнении с ранее известным лемехом.

References

1. Mel'nik V. I. Perspektivnyi metod resheniya zadach pochvoobrabotki / V. I. Mel'nik, L. N. Tishchenko // Іnzhenerіya prirodokoristuvannya.-2014.-№ 1.-S. 42-55. URL: http://nbuv.gov.ua/UJRN/Iprk_2014_1_9. .

2. Slobodyuk P.I., Pashchenko V.F., Medvedev V.V. Kombinirovannaya obrabotka pochvy // Tekhnika v sel'skom khozyaistve. – 2011. – № 3 – S. 14-15.

3. Syromyatnikov Yu.N. Povyshenie effektivnosti tekhnologicheskogo protsessa dvizheniya pochvy po lemekhu pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny. // Sel'skoe khozyaistvo. — 2017.-№ 1.-S.48-55. DOI: 10.7256/2453-8809.2017.1.22037. URL: http://e-notabene.ru/sh/article_22037.html

4. Zelenin A.N. Osnovy razrusheniya gruntov mekhanicheskimi sposobami. 2-e izd. – M.: Mashinostroenie, 1968. – 375 s.

5. Kuznetsov N.G. Sokhranenie plodorodiya pochvy pri vozdeistvii na nee khodovykh sistem traktorov i rabochikh organov mashin // Vestn. s.–kh. nauk. – 2001. – № 7. S. 115-118

6. Sidorov M.I. Sovremennye tendentsii v obrabotke pochvy // Zemledelie. – 2016. – № 4. – S. 18-21.

7. Pashchenko V.F. Onishko M.I. Snizhenie energoemkosti kombinirovannoi mashiny dlya obrabotki pochvy i poseva // Mekhanizatsiya i elektrifikatsiya sel'skogo khozyaistva: Sb. nauch. tr. UNIIMESKh. Vyp. 70. – Kiev, 1989. – S. 17-20.

8. Onishko M.I. Razrabotka i obosnovanie parametrov rabochikh organov kombinirovannoi mashiny dlya obrabotki pochvy i poseva: Dis ... kand. tekhn. nauk. – Khar'kov, 1988. – 134 s.

9. Pashchenko V.F. Modelirovanie vzaimodeistviya s pochvoi rabochego organa s gibkim elementom // Sb. nauchn. trudov KhGAU “Tekhnologiya proizvodstva i konstruirovanie sel'skokhozyaistvennykh mashin”. – Khar'kov, 1997. – S. 12-22

10. Sineokov G.N., Panov I.M. Teoriya i raschet pochvoobrabatyvayushchikh mashin. – M.: Mashinostroenie, 1977.

11. Vasilenko P.M., Medvedev V.V., Pashchenko V.F. i dr. Orudie dlya obrabotki pochvy i poseva // A.s. № 1168116. – Opubl. 23.07.85. – Byulleten' № 27.

12. Medvedev V.V., Slobodyuk P.I., Pashchenko V.F., Baglai K.I., Khlivnyak G.G. Rabochii organ dlya predposevnoi obrabotki pochvy v podsemennom sloe // Mekhanizatsiya i elektrifikatsiya s.kh. – 1986. – № 5. – S. 20-22.

13. Matsepuro E.M., Manyuta I.V. Voprosy zemledel'cheskoi mekhani¬ki. – T.2. – Minsk: Gosizdat BSSR, 1959.

Link to this article

You can simply select and copy link from below text field.

|