MAIN PAGE

> Back to contents

Electronics and Machinery

Reference:

Gubanova A.A., Martynenko A.I.

A Machine tool hydraulic station management system modeling

// Electronics and Machinery.

2017. № 3.

P. 23-32.

DOI: 10.7256/2453-8884.2017.3.24739 URL: https://en.nbpublish.com/library_read_article.php?id=24739

A Machine tool hydraulic station management system modeling

Gubanova Aleksandra Anatol'evna

Lecturer at Don State Technical University.

344000, Russia, Rostovskaya oblast', g. Rostov-Na-Donu, Gagarina, 1

|

anatoliya81@mail.ru

|

|

|

Other publications by this author

|

|

|

Martynenko Andrei Ivanovich

Postgraduate at the Department of Production Processes Automation of Don State Technical University

344000, Russia, Rostov-on-Don, pl. Gagarina, 1

|

37.1@donstu.ru

|

|

|

|

DOI: 10.7256/2453-8884.2017.3.24739

Received:

15-11-2017

Published:

26-11-2017

Abstract:

The research subject is the system of management of a machine tool hydraulic system used for hydraulic drive power supply of metal-cutting machines. The article contains the results of simulation modeling of the system in the MathLab software package and analyzes the transitional processes of these models. The authors show that the quality if a hydraulic station management determines reliability and productivity of a particular cutting unit. This problem is especially topical for cutting machines with computer numerical control used for deep-hole drilling with carbide drills within the wings for cutting oil input. Cutting oil input through the cutting zone in many aspects depends on the presence and the condition of chips in drill channels in the function of embedding (to 9d). The authors perform the simulation of pump performance management in the function of changing consumption using the MathLab modeling, since when achieving the critical pressure of 65-70 MPa, forced ejection of a drill from a cutting zone is necessary, and sometimes it is impossible to perform in reality. The authors propose simulation models, which help analyze the hydraulic station performance without technological equipment. The article considers the system of a hydraulic station management on the basis of micro PLCs Siemens S7-224XP. The authors analyze the management subsystem for a controller realizing the temperature control and cutting oil consumption law.

Keywords:

machine tool hydraulic station, simulation, CNC machine, transition process, disturbance, temperature control, temperature stabilization, controller, dynamic model, static error

This article written in Russian. You can find original text of the article here

.

Станочная гидростанция – самостоятельная технологическая единица, имеющая целый ряд отдельных подсистем: прокачки масла, подогрева или охлаждения, управления расходом, очистки масла и т.д. Одной из основных задач, решаемых станочной гидростанцией являются: контроль и регулирование давления и расхода в гидросистеме, снижение вязкости масла по средствам его нагрева до определенной температуры, подача СОЖ в зону резания с заданной подачей масла и под определенным давлением. При решении последней задачи, возникает ряд определенных сложностей, одной из которых является проблема для станков с ЧПУ, используемых для глубокого сверления отверстий в титановых сплавах твердосплавными сверлами с каналами внутри перьев для подвода СОЖ. В каналах обеспечивается давление не менее 50 МПа при регламентированном расходе масла. Нарушение технических условий приводит к разрушению инструмента. Также, в связи с тем, что условия окружающей среды, в данном случае температура, в цехе все время меняется, вязкость минерального масла колеблется (повышается или понижается) в несколько раз. Повышение вязкости масла затрудняет попадание СОЖ по каналам сверла в зону резания при сверлении, что как было указано выше, приводит к поломке инструмента.

В связи с вышеуказанным, возникает необходимость имитационного моделирования работы системы станочной гидростанции для контроля и стабилизации расхода СОЖ и прогнозирования поломки инструмента станочного оборудования.

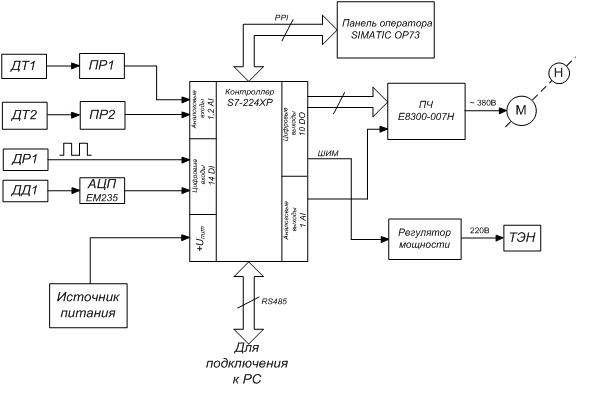

Структурная схема микропроцессорной системы управления станочной гидростанцией на базе микроконтроллера S7-224XP представлена на рисунке 1.

Рисунок 1 - Структурная схема системы управления станочной гидростанцией

Основой системы управления является программируемый логический контроллер Siemens S7-224XP, имеющий простое подключение внешних цепей через терминальные блоки с контактами.

Датчики температуры ДТ1,ДТ2 необходимы для организации работы подсистемы стабилизации температуры. Термопреобразователи предназначены для непрерывного измерения температуры различных рабочих сред (пар, газ, вода, сыпучие материалы, химические реагенты и т. п.), не агрессивных к материалу корпуса датчика. Термопреобразователи ДТ1 и ДТ2 подключаются к контролеру через вторичные преобразователи ПР1, ПР2, формирующие из изменяющегося сопротивления термопреобразователя напряжение пропорциональное этому сопротивлению, которое подается на контролер для дальнейшей обработки.

Турбинный счетчик расхода жидкости ДР1 предназначен для использования в качестве средств измерений объемного количества жидкости (нефтепродуктов) при внутрихозяйственном учете. Датчик давления ДД1 предназначен для непрерывного преобразования значения абсолютного, избыточного давления и (или) разрежения жидкостей и газов, а также разности давлений (в т.ч. уровня жидкости) в унифицированный сигнал в системах автоматического контроля, регулирования и управления технологическими процессами. Унифицированный токовый сигнал с датчика поступает на стандартный модуль АЦП SIMATIC EM235; данный модуль выпускается фирмой SIEMENS и предназначен для работы в составе автоматизированных комплексов на основе контроллеров серии S7-200.

Преобразователь частоты E8300-007H предназначен для регулирования скорости электродвигателя переменного тока, соединяется с контроллером по средствам цифровых и одного аналогового выхода.

Вал асинхронного электродвигателя мощностью 5,5 кВт через соединительную муфту соединен с валом шестеренного насоса который и обеспечивает подачу СОЖ в гидросистему. Двигатель является управляющим устройством в подсистеме стабилизации и расхода СОЖ в гидросистеме. ТЭН - трубчатые электронагреватели предназначены для преобразования электрической энергии в тепловую и применяются в качестве комплектующих изделий в промышленных установках и бытовых нагревательных приборах. Нагрев различных сред осуществляется путем конвекции, теплопроводности и излучения.

После того как сигналы с датчиков температуры пришли в контролер и программа выработала управляющее воздействие в виде сигнала ШИМ, устройство регулирования мощности подает на ТЭН необходимое количество постоянного напряжения 220 В для нагрева масла в резервуаре на определенную разницу температур[1].

Панель оператора SIMATIC OP 73 Micro, подключенная к центральному процессору S7-224XP через интерфейс PPI отображает значения параметров и дает возможность задавать переменные такие как расход, верхний и нижний уровень давления в процессе работы системы управления.

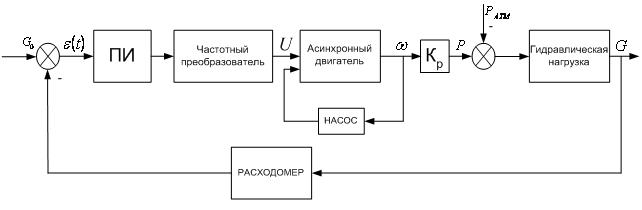

В данной подсистеме в качестве объекта управления выступает насосный агрегат, в состав которого входит асинхронный двигатель и шестеренный насос. Данный насос способен обеспечить необходимую величину подачи СОЖ в гидросистеме. Благодаря системе управления и наличию датчика обратной связи (расходомера), в системе поддерживается постоянный расход при изменяющейся гидравлической нагрузке h=h(θ)[2].

В качестве устройства управления используется микроконтроллер S7-214, формирующий закон управления ПИ-регулятор и частотный преобразователь, управляющий скоростью вращения асинхронного двигателя, представляющий собой апериодическое звено.

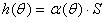

Структурная схема подсистемы контроля и стабилизации расхода СОЖ в гидросистеме выглядит следующим образом:

Рисунок 2 – Структурная схема подсистемы контроля и стабилизации расхода СОЖ

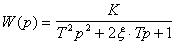

В данной подсистеме частотный преобразователь представлен апериодическим звеном и его передаточная функция имеет вид:

, (1) , (1)

Передаточная функция асинхронного двигателя:

, (2) , (2)

Гидравлическое сопротивление системы в функции зависимости от температуры выражено формулой (3):

, (3) , (3)

где α(θ) – температурный коэффициент;

S – площадь поперечного сечения напорного трубопровода.

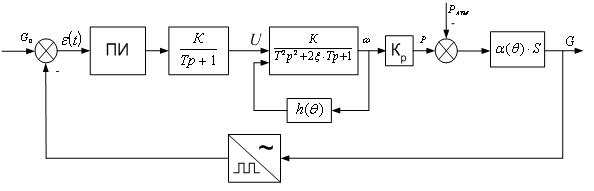

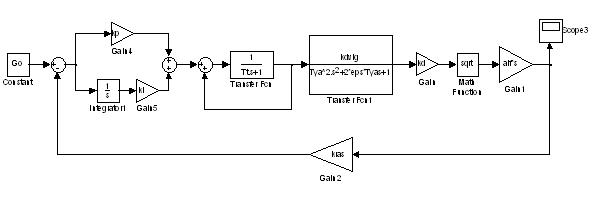

Динамическая модель подсистемы контроля и стабилизации расхода в функции зависимости от производительности насосного агрегата представлена на рисунке 3.

Рисунок 3 – Динамическая модель подсистемы контроля и стабилизации расхода СОЖ

На основании анализа математической модели и структурной схемы построим динамическую модель данной подсистемы в программном пакете MathLab/Simulink. Для моделирования подсистемы использовались следующие исходные данные представленные в сводной таблице 1.

Таблица 1- Исходные данные для динамического расчета

|

Коэффициент усиления тиристорного преобразователя, kt,

|

12

|

|

Постоянная времени тиристорного преобразователя, Тt,

|

0,02 с

|

|

Сопротивление ТЭНа, R, Ом

|

5

|

|

Плотность масла,ro ,

|

720

|

|

Удельная теплоемкость масла, С,

|

1050

|

|

Объем резервуара в котором происходит нагрев, v, м3

|

0,0012

|

Результирующая динамическая модель с единичной обратной связью по температуре представлена на рисунке 4.

Рисунок 4 – Динамическая модель подсистемы стабилизации темпиратуры с единичной обратной связью

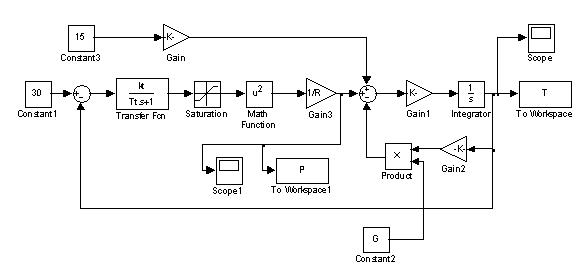

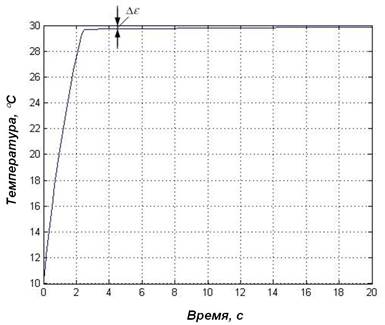

Для анализа работы системы построим графики переходных процессов по температуре и мощности ТЭНа при воздействии постоянного возмущающего воздействия.

Рисунок 5 – Переходной процесс по температуре с единичной ООС

Как видно из рисунка 5, при воздействии возмущающего воздействия с разницей в 15°С появляется статическая ошибка ∆ε»9°С. Время переходного процесса составляет около 7с.

Как известно, из теории управления для снижения статической ошибки необходимо применить регулятор. Для решения данной задачи воспользуемся стандартным ПИ-регулятором[3]. Коэффициенты регулятора ki-коэффициент интегрирования и kp-коэффициент пропорциональности были подобраны экспериментально, и представлены в таблице 2.

Таблица 2- Коэффициенты ПИ-регулятора

|

Коэффициент усиления тиристорного преобразователя, kt,

|

12

|

|

Коэффициент пропорциональности, kp

|

10

|

|

Коэффициент интегрировании,ki

|

0,5

|

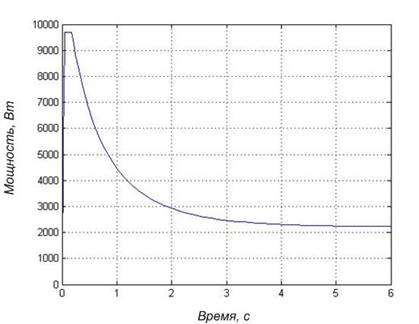

Переходной процесс по мощности выделяемой ТЭНом на нагрев масла представлен на рисунке 6.

Рисунок 6 – Переходной процесс по мощности с единичной ООС

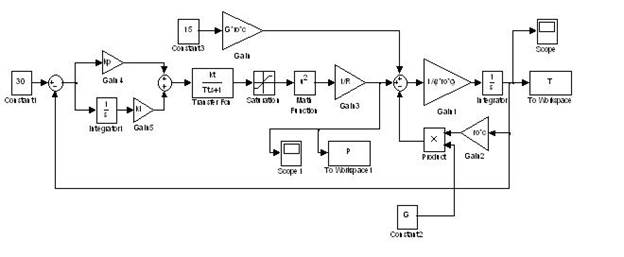

Результирующая динамическая модель с ПИ-регулятором представлена на рисунке 7.

Рисунок 7 – Динамическая модель подсистемы стабилизации температуры с ПИ-регулятором

Переходные процессы по температуре и мощности ТЭНа в системе с применением ПИ-регулятора.

Рисунок 8 – Переходной процесс по температуре с ПИ-регулятором

Как видно, при применении ПИ-регулятора удалось снизить статическую ошибку до ∆ε»0,3°С, а так же значительно сократить время переходного процесса ( примерно 3с).

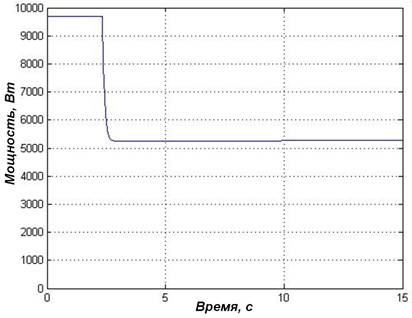

Переходной процесс по мощности выделяемой ТЭНом на нагрев масла представлен на рисунке 9.

Рисунок 9 – Переходной процесс по температуре с ПИ-регулятором

Представим результаты моделирования подсистемы контроля и стабилизации температуры СОЖ. Для моделирования подсистемы использовались следующие исходные данные представленные в сводной таблице 3.

Таблица 3- Исходные данные для динамического расчета

|

Коэффициент усиления тиристорного преобразователя, kt,

|

12

|

|

Заданное значение расхода, Go

|

0,042

|

|

Коэффициент ,eps

|

0,7

|

|

Постоянная времени цепи якоря, Tya,c

|

0,1

|

|

Коэффициент усиления двигателя, kdvig

|

0,1

|

|

Объем резервуара в котором происходит нагрев, v, м3

|

0,0012

|

|

Коэффициент усиления тиристорного преобразователя, kt

|

0,1

|

|

Постоянная времени тиристорного преобразователя,Tt

|

0,02

|

|

Коэффициент пропорциональности, kp

|

0,1

|

|

Коэффициент интегрировании,ki

|

0,1

|

|

Коэф. Преобразования скор. вращ. двиг в давление kd

|

1

|

|

Гидравлическое сопротивление насоса h

|

10

|

|

Площадь поперечного сечения трубопровода,s,м2

|

0,00001256

|

|

Коэф. учитывающий гидросопротивление трубопровода alf

|

0,1

|

|

Коэф. Преобразования давления в расход kras

|

10

|

Результирующая динамическая модель с единичной обратной связью по температуре СОЖ представлена на рисунке 10.

Рисунок 10 – Динамическая модель подсистемы стабилизации расхода СОЖ с ПИ-регулятором

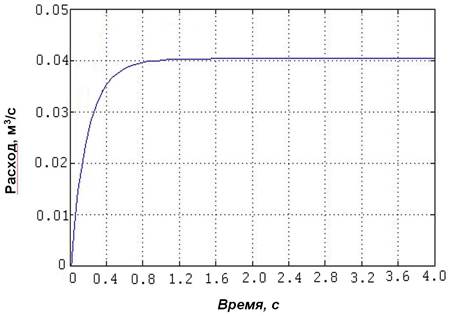

Для анализа работы системы построим графики переходных процессов по расходу при воздействии постоянного возмущающего воздействия.

Рисунок 11 – Переходной процесс по расходу СОЖ

Как видно, расход СОЖ стремится к номинальной (0,042м3/c), а время регулирования составляет приблизительно 1,6 секунды. При этом перерегулирование нет. Следовательно, можно сделать вывод, что система показывает устойчивую работу с хорошим запасом.

В статье рассмотрена система управления станочной гидростанцией на базе микроПЛК Siemens S7-224XP. Проведен анализ подсистемы управления для контроллера реализующий закон управления температурой и расходом СОЖ. В ходе исследования было произведено моделирование работы системы управления в программном пакете MatLAB и проанализированы переходные процессы полученные в результате моделирования. Применение имитационной системы управления станочной гидростанцией позволяет снизить трудоемкость и повысить производительность процесса механообработки (сверления) для станков с ЧПУ.

References

1. Sveshnikov V. K. Usov A. A. Stanochnye gidroprivody. Spravochnik. – M.: Mashinostroenie, 1995.-448 s.

2. Lovygin A.A., Vasil'ev A.V., Krivtsov S.Yu. Sovremennyi stanok s ChPU i CAD_CAM, 2006.-286 s.

3. Dyadik V.F. Teoriya avtomaticheskogo upravleniya: uchebnoe posobie/ V.F. Dyadik, S.A. Baidali, N.S. Krinitsyn; Natsional'nyi issledovatel'skii Tomskii politekhnicheskii universitet. − Tomsk: Izd-vo Tomskogo politekhnicheskogo universiteta, 2011. – 196 s

Link to this article

You can simply select and copy link from below text field.

|