|

DOI: 10.7256/2453-8809.2019.2.31975

Received:

15-01-2020

Published:

25-03-2020

Abstract:

The subject of the research is the operation process of the rotor of a tilling and separating machine which changes the structure and solidity of the cultivated soil layer according to the agricultural requirements. The author considers the design of the blade of the rotor of a tilling and separating machine. The research object is the blade of the rotor whose form allows it to rotate with a minimum expenditure of energy. The topicality of the research is determined by the fact that the theoretically justified design of the blade of the rotor of a tilling and separating machine will help improve the methods of secondary tillage aimed at the improvement of its agrotechnical characteristics with a minimum expenditure of energy. To define the value of a relative speed of a soil element movement along the blade, the author derives an equation using the method described in P.M. Vasilenko’s theory of soil particles movement along rough surfaces, but the author considers soil particles movement along the blade. The article is based on theoretical research using mechanical and mathematical modeling of working tools interaction with soil. The initial data was collected via the analysis of literary sources. The author substantiates the design of the blade of the rotor of a tilling and separating machine which guarantees its rotation with a minimum expenditure of energy owing to the lesser dispersion of soil particles and the prevention of their building-up on the separating grill. The research results can be used by constructors and specialists developing tillage tools.

Keywords:

the soil, rotor, separation lattice, knife, energy, torque, loosening, design, angle, radius

This article written in Russian. You can find original text of the article here

.

Предметом исследования является процесс функционирования рабочих органов ротора почвообрабатывающей рыхлительно-сепарирующей машины изменяющей структуру и плотность обрабатываемого слоя почвы в соответствии с агро-требованиями. Рассмотрена конструкция ножа ротора рыхлительно-сепарирующего устройства почвообрабатывающей машины. Для определения значения относительной скорости движения элемента почвы по лезвию ножа ротора составили дифференциальное уравнение относительно движения элемента почвы по лезвию ножа, воспользовавшись для этого методом изложенным в теории движения частицы почвы по шероховатым поверхностям П.М. Василенко, но при этом рассмотрено движение элемента почвы не по поверхности, а по лезвию ножа. Объектом исследования является нож ротора, форма рабочей кромки которого обеспечивает его вращение с минимальными затратами энергии на работу. При выполнении работы применены теоретические исследования с использованием механико-математического моделирования взаимодействия рабочих органов с почвой. Исходная информация для обоснования исследования получена путем анализа литературных источников. Дано обоснование конструкции ножа ротора рыхлительно-сепарирующего устройства почвообрабатывающей машины которая обеспечит его вращение с минимальными затратами энергии на работу при условии уменьшения разбрасывания почвы, и предотвращения сгруживания ее на сепарирующей решетке. Актуальность заключается в том, что теоретически обоснованая конструкция ножа ротора рыхлительно-сепарирующего устройства почвообрабатывающей машины позволит усовершенствовать методы предпосевной обработки почвы для улучшения ее агротехнических качеств, с минимальными затратами энергии. Целевая группа потребителей информации в статье - конструкторы, специалисты занимающиеся разработкой почвообрабатывающих рабочих органов.

Ключевые слова:почва, крутящий момент, работа ножа, энергия, сепарирующая решетка, ротор.

Введение. Технологические операции обработки почвы при безотвальной системе земледелия направлены на создание благоприятных условий для накопления и сохранения влаги, роста и развития растений, контроля сорняков.

Задачей предпосевной обработки почвы является рыхление верхнего слоя на глубину заделки семян, обеспечение мелкокомковатого строения посевного слоя, выравнивание поверхности поля, уплотнение семенного ложа, заделка внесенных удобрений, уничтожение проросших сорняков и сохранение влаги в обрабатываемом слое почвы [1].

Предпосевная обработка почвы сопровождается перераспределением мелких и крупных частиц по глубине обрабатываемого слоя. Рабочие органы орудий, перемещаясь в почве, выталкивают большие комки на поверхность, а мелкие просыпаются вниз [2, 3]. С увеличением количества обработок перераспределение частиц почвы, то есть ее сепарация по глубине обработки, усиливается. Причем многократные обработки почвы перед посевом приводят к увеличению числа крупных частиц почвы в зоне заделки семян, что является нежелательным [4].

Сепарация почвы достаточно энергоемкий процесс, так как при скорости движения агрегата 2 м/с через нее надо пропускать в одну секунду около 20 кг почвы. При этом необходимо обеспечить хорошее ее измельчение.

Существует почвообрабатывающая машина «Докучаевская» ПРСМ-5 (стратификатор) для оптимизации физико-механического состояния почвы, с помощью перераспределения агрономически ценной фракции по глубине обрабатываемого слоя [5].

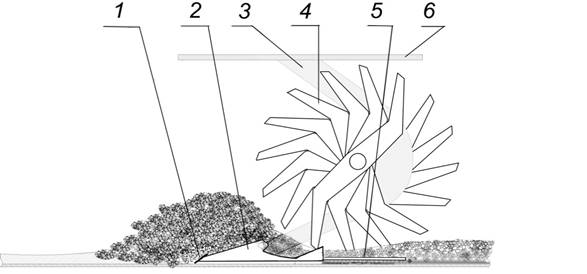

На рисунке 1 показан общий вид машины.

|

|

|

Рис. 1. Почвообрабатывающая машина «Докучаевская» ПРСМ-5 (стратификатор): 1 – рама; 2 – лемех с сепарирующими решетками; 3 – ротор с рыхлителями

|

Почвообрабатывающая машина состоит из рамы, двух опорных колес, плоскорежущих стрельчатых лап [6], к которым приварены прутки сепарирующей решетки, ротора и его привода. Привод ротора осуществляется от вала отбора мощности трактора. Глубина обработки почвы регулируется с помощью винтовых механизмов опорных колес.

|

|

|

Рис. 2. Принципиальная схема почвообрабатывающей машины: 1 – наральник; 2 – лемех; 3 – стойка; 4 – рабочий орган ротора; 5 – сепарирующая

|

Работает машина следующим образом (рис. 2). Во время движения, наральник 1, установленный на стрельчатые лапе 2 установленной на стойке 3 закрепленной на раме 6, обеспечивает углубление в уплотненный слой почвы [7, 8]. Подрезанный стрельчатой лапой 2 слой почвы поднимается, частично крошится, загнутые концы лапы не дают сходить почве с рабочего органа в стороны [9]. Стрельчатая лапа (лемех) 2, обеспечивает подъем слоя почвы, который поднимаясь, частично крошится, образуя почвенное ядро перед лемехом, и движется, попадая на сепарирующую решетку 5 [10]. Ножи ротора 4 захватывают почву, крошат и перемещают ее по решетке. Мелкие комочки проходят через зазоры сепарирующей решетки, при этом на поверхность почвы выбрасываются большие комки, пожнивные остатки, и растения с корнем, в том числе и корневища сорняков. В результате происходит сепарация обрабатываемого слоя почвы, расслоение его по структурному составу, уничтожения сорняков путем их механического вычесывания из обрабатываемого слоя, а на поверхности образуется слой мульчи [5]. Однако ножи активного рабочего органа (ротора) не исключают возможности заклинивания почвы между ножом и прутьями в момент входа его в сепарирующую решетку.

Из литературных источников известно, что затраты энергии на привод ротора будут минимальными при наименьших значениях его радиуса и угловой скорости вращения, которые допускаются поступательной скоростью движения машины и агротехническими требованиями [11, 12, 13, 14]. Определено, что снижение энергоемкости наиболее нагруженного рабочего органа возможно за счет изменения его параметров. Перспективное направление снижения энергоемкости – изменение формы. При этом изменяются или общие параметры за счет переменного угла резания, или же только форма режущей кромки. [15, 16, 17]

В нашей почвообрабатывающей машине мелкокомковатая структура почвы в зоне заделки семян обеспечивается путем перераспределения ее частиц по глубине посевного слоя, что исключает необходимость интенсивно крошить почву [18, 19, 25]. Нож ротора в момент входа в почву не должен препятствовать движению ее по сепарирующая решетке [20, 21].

В процессе работы почвообрабатывающей рыхлительно-сепарирующей машины около 30% от общих затрат энергии расходуется на привод ротора. Одним из основных факторов, определяющих энергоемкость работы ножа ротора является профиль его рабочей кромки. При взаимодействии ножа ротора с почвой крутящий момент не является величиной постоянной и меняется со временем в зависимости от положения относительно сепарирующей решетки.

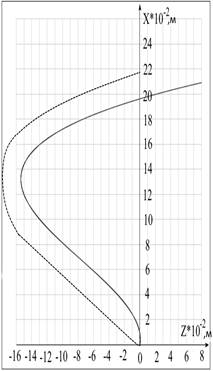

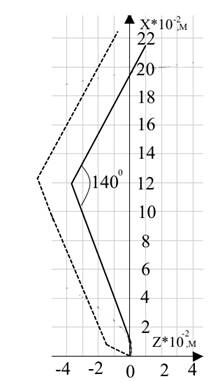

Анализ работы показал, что крутящий момент достигает наибольшей величины при максимальном погружении его в почву, то есть в момент входа его в промежутки сепарирующей решетки [22]. С помощью метода прямого вариационного исчисления была получена форма рабочей кромки ножа, которая обеспечивает минимальные затраты энергии на работу как отдельного ножа, так и ротора в целом. Наиболее полным показателем работы ножа ротора является расход энергии на выполнение одного полного цикла, то есть одного оборота ножа [22]. Рассмотрена работа ножа ротора рыхлительное-сепарирующей машины в положениях относительно почвы и сепарирующей решетки. Три фазы работы ножа ротора, с момента вхождения ножа в почву до сепарирующей решетки, момента движения ножа над сепарирующей решеткой, с момента движения ножа над сепарирующей решеткой до выхода ножа из почвы [23]. Кривая линия (рис 3), построенная по уравнению

Z=0,2575 Х – 30,268 Х2 +147,4458Х3 (1)

показывает рациональный профиль рабочей части ножа ротора с минимальными затратами энергии на его работу, обеспечивает наилучшие условия для транспортировки почвы в начальный момент вхождения его в почву и минимальные затраты энергии на его привод [24].

Рис. 3. Профиль рабочей части ножа ротора обеспечивающий минимальные затраты энергии на его работу

Однако не исключает возможности заклинивания почвы между ножом и прутьями в момент входа его в сепарирующую решетку.

Цель исследования.Обосновать конструкцию ножа ротора рыхлительно-сепарирующего устройства почвообрабатывающей машины, обеспечивающую его вращение с минимальными затратами энергии на работу при условии уменьшения разбрасывания почвы и предотвращения сгружування ее на сепарирующей решетке.

Материалы и методы. Угол между ножами, радиус ротора, количество ножей, геометрические параметры ножа, расстояния между ножами, являются конструктивными параметрами ротора, которые зависят друг от друга

Минимальный радиус ротора Rmin выбирается с таким расчетом, чтобы его ножи проходили в промежутках сепарирующей решетки по всей его рабочей длине. При этом ось ротора должна располагаться над поверхностью почвы, находящейся на сепарирующей решетке [24].

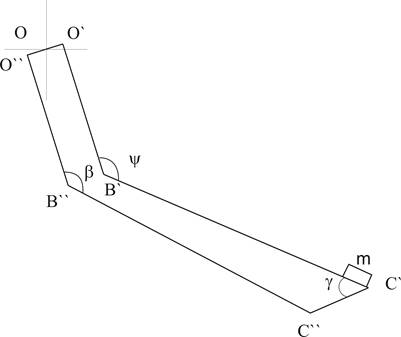

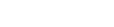

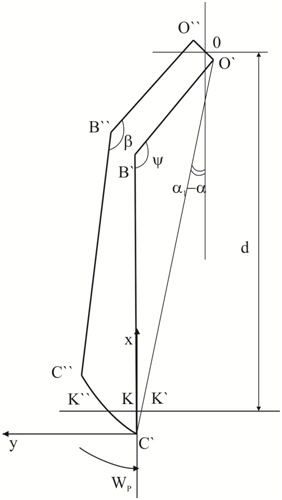

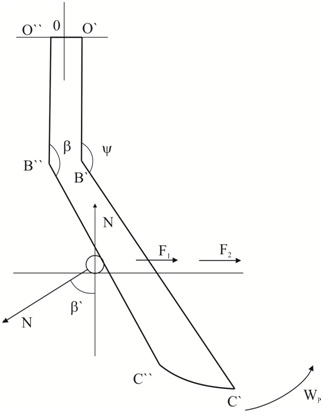

Геометрические параметры ножа ротора при известном радиусом определяются углами ψ, γ и β (рис. 4).

|

|

|

Рис. 4. Схема ножа ротора

|

В одну из задач технологического процесса почвообрабатывающей рыхлительно-сепарирующей машины входит сепарация обрабатываемого слоя почвы, расслоение его по структурному составу. В результате на поверхность почвы должны выбрасываться крупные комочки почвы, пожнивные остатки, и растения с корнем.

|

А А

Б Б

|

|

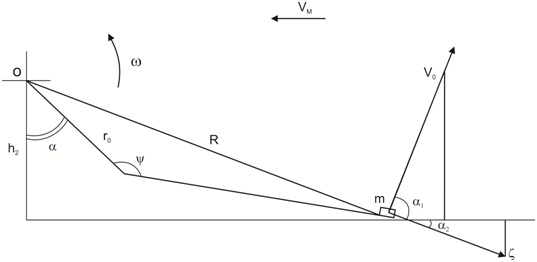

Рис. 5. Схема к определению конструктивного угла ножа ротора ψ

|

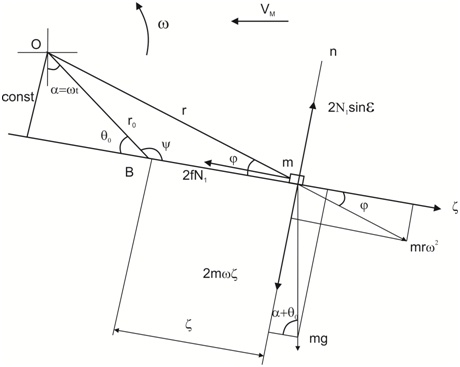

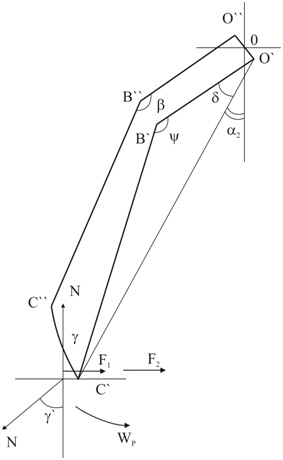

Для достижения последнего геометрические параметры ножа ротора при известном радиусе определяются углом ψ наклона пологой касательной к профилю ножа в наиболее неблагоприятном его положении (рис. 5). Наименьший угол наклона касательные к профилю ножа будут иметь после выхода его из почвы перемещающейся по сепарирующей решетке. Для обоснования угла ψ рассмотрим движение элемента почвы по лезвию ножа ротора при условии, что ротор вращается в плоскости относительно точки «0» с постоянной угловой скоростью ω=const. Элемент почвы «m» совершает сложное движение: переносное – вокруг точки «0» и относительное – по лезвию ножа ротора.

Задача ножа ротора состоит в том, чтобы перемещать почву по сепарирующей решетке, предотвращать ее залипание и выталкивать крупные частицы почвы на поверхность. При этом разбрасывание почвы должно быть сведено к минимуму. Как видно из рис. 5, с уменьшением величины угла ψ выталкивающая способность ножа ротора повышается. Однако при этом уменьшается относительная скорость движения элемента почвы «m» по лезвию ножа ротора, что может привести к смещению почвы по ходу движения машины и ее сгруживанию на сепарирующей решетке.

Следовательно, результирующая скорость схода частицы почвы с лезвия ножа не должна превышать поступательной скорости движения комбинированной машины и должна быть направлена горизонтально в сторону, противоположную этой скорости, то есть (см. рис. 5 а)

(2) (2)

где V – результирующая скорость схода элемента почвы «m» с ножа ротора, м/с; VM – поступательная скорость машины, м/с; V0 – окружная скорость ротора, м/с;  – относительная скорость элемента почвы «m» по лезвию ножа ротора, м/с. – относительная скорость элемента почвы «m» по лезвию ножа ротора, м/с.

Однако, при заданных частоте вращения ротора и его радиусе, выполнить это условие не представляется возможным. Поэтому для уменьшения разбрасывания почвы и предотвращения сгруживания ее на сепарирующей решетке угол ψ выбираем таким, чтобы сумма проекций составляющих равнодействующей скорости схода частицы почвы с ножа ротора на горизонтальную плоскость равнялась поступательной скорости машины и была направлена в противоположную сторону.

Основанием для выполнения этих требований являются следующие предпосылки. Как показано на рис. 5 а, перемещение элемента почвы по лезвию ножа будет обусловливаться соотношением между геометрическими параметрами ножа (размером начального радиуса  и углом ножа ψ) а также кинематическими элементами вращательного движения ротора (значением угла α и угловой скоростью ω). и углом ножа ψ) а также кинематическими элементами вращательного движения ротора (значением угла α и угловой скоростью ω).

Во время схода, для выполнения указанных условий, необходимо, чтобы (см. рис. 5 а)

(3) (3)

Отсюда относительная скорость движения частицы по лезвию ножа  определяется по формуле определяется по формуле

, (4) , (4)

Как видно из рисунка 5 а)

, (5) , (5)

, (6) , (6)

Тогда

. (7) . (7)

где h2 – расстояние от оси вращения ротора к поверхности почвы, находящейся на сепарирующей решетке, r0 – начальный радиус ножа, ψ – угол ножа.

Для определения значения  составляем дифференциальное уравнение относительно движения элемента почвы «m» по лезвию ножа, воспользовавшись для этого методом, изложенным в теории движения частицы почвы по шероховатым поверхностям П.М. Василенко. Но при этом рассмотрим движение элемента почвы не по поверхности, а по лезвию ножа. составляем дифференциальное уравнение относительно движения элемента почвы «m» по лезвию ножа, воспользовавшись для этого методом, изложенным в теории движения частицы почвы по шероховатым поверхностям П.М. Василенко. Но при этом рассмотрим движение элемента почвы не по поверхности, а по лезвию ножа.

Результирующая реакций поверхностей кромок ножа определится из выражения

(8) (8)

где   и и   – реакции поверхностей кромок ножа ротора, Н. – реакции поверхностей кромок ножа ротора, Н.

Причем, полагаем, что  . .

Результирующая этих сил равна

(9) (9)

где ε – угол образуемый ножом по мере погружения в почву

Силы трения элемента почвы «m» о металл лезвия ножа ротора направлены вдоль двух кромок ножа в сторону, противоположную направлению относительной скорости  . Результирующая этих сил равна . Результирующая этих сил равна

(10) (10)

где φ – угол наклона равнодействующей сил сопротивления

Будем полагать, что прямолинейный нож ротора вращается в плоскости относительно точки О с постоянной угловой скоростью w. Элемент почвы с массой m осуществляет сложное движение: переносный - вокруг точки О и относительный - по лезвию ножа ротора. Кроме того, на элемент почвы «m» действует сила инерции mrω2, сила тяжести mg (его вес), Кориолисова сила  , нормальная сила N и сила трения Nf. , нормальная сила N и сила трения Nf.

Движение частицы будет обеспечено при выполнении условия

. (11) . (11)

Проецируя на нормаль к ножу все действующие на долю силы, получим значение нормальной силы

. (12) . (12)

Связь расстояния ζ с углами a и θ0 находится с помощью известных формул решения косоугольных и прямоугольных треугольников (см. рис. 5):

(13) (13)

где h – расстояние от оси вращения ротора к поверхности почвы, находящейся на сепарирующей решетке.

После преобразования уравнения получим

(14) (14)

Уравнения движения в проекциях на принятые оси координат  и n запишутся и n запишутся

(15) (15)

(16) (16)

Из рисунка 5 видно, что

(17) (17)

(18) (18)

где  – расстояние элемента «m» почвы от точки В; m - масса элемента почвы; – расстояние элемента «m» почвы от точки В; m - масса элемента почвы;  - ускорение движения элемента почвы по лезвию ножа ротора; ω - угловая скорость вращения ножа ротора; - ускорение движения элемента почвы по лезвию ножа ротора; ω - угловая скорость вращения ножа ротора;  - относительная скорость движения элемента почвы по лезвию ножа ротора; r - радиус вращения элемента почвы; φ - угол между радиусом вращения элемента почвы и лезвием ножа ротора; f - коэффициент трения; α - угол поворота ножа ротора; θ0 - угол между прямой, проходящей по лезвию ножа и его плечом; N1 - сила нормального действия ножа ротора на элемент почвы. r0 - начальный радиус ножа; g – ускорение свободного падения. - относительная скорость движения элемента почвы по лезвию ножа ротора; r - радиус вращения элемента почвы; φ - угол между радиусом вращения элемента почвы и лезвием ножа ротора; f - коэффициент трения; α - угол поворота ножа ротора; θ0 - угол между прямой, проходящей по лезвию ножа и его плечом; N1 - сила нормального действия ножа ротора на элемент почвы. r0 - начальный радиус ножа; g – ускорение свободного падения.

Исключив из уравнения (15) нормальную реакцию N1 и с учетом уравнения (17), получим

(19) (19)

или

(20) (20)

где

; (21) ; (21)

; (22) ; (22)

; (23) ; (23)

(24) (24)

Решив уравнение (20) и определив произвольные постоянные при условии  =0 и =0 и  =0 при t=0, получим =0 при t=0, получим

, (25) , (25)

где

; (26) ; (26)

; (27) ; (27)

; (28) ; (28)

; (29) ; (29)

; (30) ; (30)

; (31) ; (31)

. (32) . (32)

Для определения относительной скорости движения элемента почвы «m» по лезвию ножа, дифференцируем уравнение (25), получим  (33) (33)

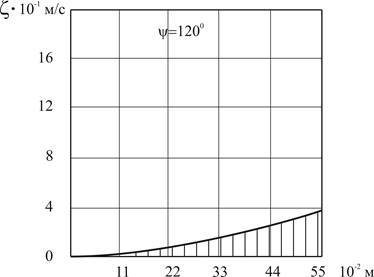

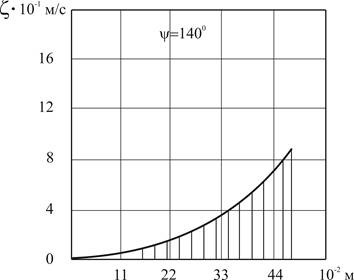

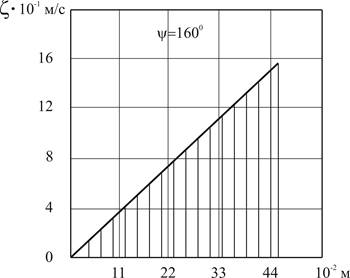

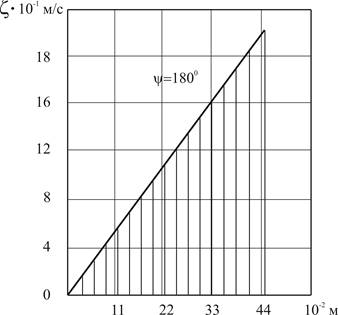

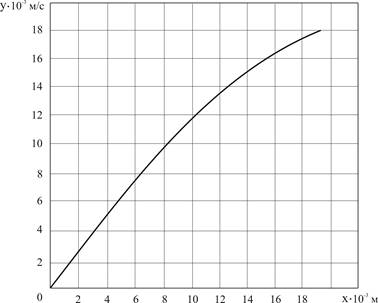

Для определения  на конце ножа ротора необходимо построить эпюры относительных скоростей движения почвы по лезвию ножа ротора. Такие эпюры (рис. 6) построены на основании уравнений (25) и (33) при значениях φ=26030′, ε=300, ω=18,84 c-1, R=0,73 м. Величину t находим с учетом конструктивных и кинематических параметров ротора. Значения r0 принимались равными 0,28; 0,41; 0,53 и 0,66 м. на конце ножа ротора необходимо построить эпюры относительных скоростей движения почвы по лезвию ножа ротора. Такие эпюры (рис. 6) построены на основании уравнений (25) и (33) при значениях φ=26030′, ε=300, ω=18,84 c-1, R=0,73 м. Величину t находим с учетом конструктивных и кинематических параметров ротора. Значения r0 принимались равными 0,28; 0,41; 0,53 и 0,66 м.

|

|

|

|

|

|

|

|

|

Рис. 6. Эпюры относительных скоростей движения почвы по лезвию ножа ротора:ψ=1200; ψ=1400; ψ=1600; ψ=1800

|

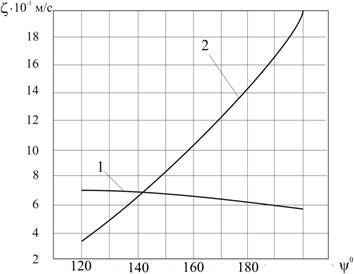

По уравнению (7) и полученным эпюрам скоростей построены зависимости относительной скорости движения элемента почвы при сходе с лезвия ножа ротора в зависимости от значения угла ножа ротора ψ (рис. 7).

|

|

|

Рис. 7. Зависимость относительной скорости движения элемента почвы на конце ножа ротора от величины угла ψ: 1 – необходимая относительная скорость движения; 2 – относительная скорость движения почвы, определенная из эпюр скоростей

|

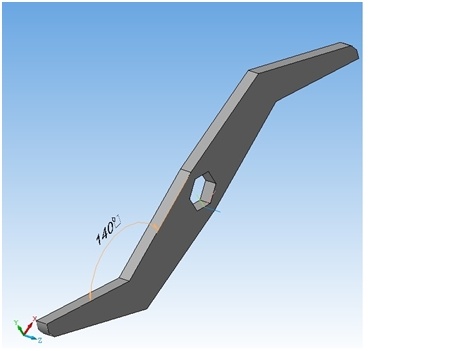

Из рис. 7 видно, что при заданных параметрах ножа ротора и частоте его вращения при ψ=1420 разбрасывание почвы и ее сгруживание на сепарирующей решетке отсутствуют. Следовательно, оптимальным можно считать угол ψ, близкий к 1420, соответственно исходя из рис. 5 значение угла q0 между прямой, проходящей по лезвию ножа и его плечом равно 380.

Тогда уравнение кривой профиля ножа ротора при условии уменьшения разбрасывания почвы и предотвращения сгруживания ее на сепарирующей решетке описывается следующим образом [24]:

(34) (34)

Профиль ножа ротора обеспечивающий его вращение с минимальными затратами энергии при условии уменьшения разбрасывания почвы и предотвращения сгруживания ее на сепарирующей решетке показан на рис. 8.

|

|

|

Рис. 8. Профиль ножа ротора рыхлительно-сепарирующего устройства, обеспечивающий его вращение с минимальными затратами энергии при условии уменьшения разбрасывания почвы и предотвращения сгруживания ее на сепарирующей решетке

|

Угол γ выбирается из условия препятствия заклинивания почвы во время опускания кромки ножа ротора (рис. 9) в зазоры сепарирующей решетки. То есть

, (35) , (35)

, (36) , (36)

. (37) . (37)

Тогда

(38) (38)

При вращении ротора положение кромки  по сепарирующей решетки меняется, а угол по сепарирующей решетки меняется, а угол  должен удовлетворять неравенству (38). должен удовлетворять неравенству (38).

|

|

|

Рис. 9. Схема для определения угла  конструктивных параметров ножа ротора конструктивных параметров ножа ротора

|

Для получения уравнения кривой кромки  через точку через точку  проводим Декартовые оси координат x и y (рис. 10), которые перемещаются вместе с ножом ротора. Точку пересечения кромки проводим Декартовые оси координат x и y (рис. 10), которые перемещаются вместе с ножом ротора. Точку пересечения кромки с сепарирующей решеткой соединяем прямой с носком ножа с сепарирующей решеткой соединяем прямой с носком ножа  . .

Тогда из

(39) (39)

Из рис. 9 имеем

, (40) , (40)

(41) (41)

где а – угол поворота ножа ротора относительно начала его вхождения в зазоры сепарирующей решетки, в град.

|

|

|

Рис. 10. Схема для определения уравнения кривой кромки C'C'' через точку C'

|

Величину х находим через угол поворота ножа ротора α из  (рис. 10), используя теорему синусов (рис. 10), используя теорему синусов

, (42) , (42)

Тогда

(43) (43)

где  – расстояние от оси ротора до сепарирующей решетки, м. Кривая кромки – расстояние от оси ротора до сепарирующей решетки, м. Кривая кромки  строится по уравнению (42) и (43) (рис. 11). строится по уравнению (42) и (43) (рис. 11).

|

|

|

Рис. 11. Кривая кромки ножа ротора из условия препятствия заклинивания почвы при опускании его в зазоры сепарирующей решетки

|

Угол β выбирается таким, чтобы в самом нижнем положении кромки  частицы почвы не заклинивались между кромкой ножа и сепарирующей решеткой (рис. 12). частицы почвы не заклинивались между кромкой ножа и сепарирующей решеткой (рис. 12).

|

|

|

Рис. 12. Схема к определению угла β конструктивных параметров ножа ротора

|

Это соответствует неравенству

, (44) , (44)

, (45) , (45)

, (46) , (46)

. (47) . (47)

Тогда

. (48) . (48)

Результаты и обсуждение. Конструкцию ножа ротора рыхлительно-сепарирующего устройства который обеспечивает его вращение с минимальными затратами энергии на работу при условии уменьшения разбрасывания почвы, предотвращения сгруживания почвы на сепарирующей решетке, препятствия заклинивания почвы при опускании его в зазоры сепарирующей решетки, определили с помощью программы КОМПАС-3D V14 (рис. 13).

Расположение ножей на валу ротора влияет на изменение приводного момента и равномерность хода машины. Поэтому размещать ножи нужно по спирали с постоянным угловым шагом симметрично относительно продольной оси машины для исключения крутящих моментов в поперечной плоскости, способных нарушить устойчивость хода машины по направлению движения и по глубине.

В нашем случае ножи размещены на валу по винтовой линии с числом заходов, равным числу ножей на валу, причем начало первой винтовой линии должно совпадать в противоположной части вала с концом второй винтовой линии и т.д. Кроме того ножи необходимо располагать равномерно по всей окружности вала с угловым расстоянием между смежными ножами.

|

|

|

Рис. 13. Твердотельная модель ножа ротора с углом наклона ψ=1400 при котором разбрасывание почвы и ее сгруживание на сепарирующей решетке отсутствуют, затраты энергии на работу минимальные

|

(50) (50)

где n – число ножей.

На рис. 14 показан пример размещения 18 ножей закрепленных по парам симметрично относительно продольной оси.

|

|

|

Рис. 14. Ротор почвообрабатывающей рыхлительно-сепарирующей машины с 18 ножами закрепленных по парам симметрично относительно продольной оси

|

В табл. 1 показан угол смещения между смежными ножами αz в зависимости от количества установленных на валу ножей и их последовательность вступления в работу.

Таблица 1. Последовательность вступления в работу ножей и угол смещения между ними

|

Число ножей ротора 2n

|

Угол смещения между смежными ножами αz

|

Последовательность вступления в работу ножей

|

|

5

|

35о 0/

|

1 – 4 – 2 – 5 – 3

|

|

7

|

25о 42/

|

1 – 5 – 2 – 6 – 3 – 7 – 4

|

|

8

|

33о 45/

|

1 – 4 – 7 – 2 – 5 – 8 – 3 – 6

|

|

9

|

20о 0/

|

1 – 6 – 2 – 7 – 3 – 8 – 4 – 9 – 5

|

Приведенный выше анализ показывает, что определенному числу ножей соответствует вполне определенный угол смещения и последовательность вступления в работу.

Очевидно что, уменьшение или добавление ножей без изменения расстановки может привести к ухудшению устойчивости движения машины и увеличению неравномерности крутящего момента.

Выводы. Определено, что при заданных параметрах ножа ротора и частоте его вращения оптимальным можно считать угол ψ между наиболее пологой касательной к профилю ножа и прямой, проходящей по нерабочей его части, близкий к 1420, при котором разбрасывания почвы и ее сгружування на сепарирующей решетке отсутствуют.

Определенная с помощью программы КОМПАС-3D V14 конструкция ножа ротора рыхлительно-сепарирующего устройства почвообрабатывающей машины обеспечит его вращения с минимальными затратами энергии на работу при условии уменьшения разбрасывания почвы и предотвращения сгруживания его на сепарирующей решетке.

References

1. Nugis E. et al. Estimation of soil structure and physical state in the seedbed under different tillage and environmental conditions // Zemdirbyste-Agriculture. – 2016. – T. 103. – №. 3.DOI 10.13080/z-a.2016.103.031

2. Kovalev M.M., Sheichenko V.A., Shevchuk V.V., Fadeev V.G. Opredelenie kachestva obrabotki pochvy igol'chatoi boronoi // Traktory i sel'khozmashiny. 2016. №10. s. 11-13.

3. Sheichenko V., Dudnikov I., Shevchuk V., Kuzmych A. Research of surface-plane and space-deep interaction of needle with soil // VII International scientific congress agricultural machinery, proceedings volume 2 uses of machines. innovative technologies. conserving soils and water. 26.06 – 29.06.2019 Burgas, Bulgaria ISSN 2535-0269 (Print) ISSN 2535-0277 (Online), Agricultural machinery 2019, Vol 2., s.93-97.

4. Pashchenko V. F., Syromyatnikov Yu.N. Pochvoobrabatyvayushchaya pristavka k zernovoi seyalke v tekhnologiyakh «No till» // Aekonomika: ekonomika i sel'skoe khozyaistvo, 2018. №3 (27). – S. 6.

5. Syromyatnikov Yu.N. Pokazateli kachestva raboty pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny // Sel'skokhozyaistvennye mashiny i tekhnologii. 2018. T. 12. N3. S. 38-44. DOI 10.22314/2073-7599-2018-12-3-38-44

6. Syromyatnikov Yu.N. Obosnovanie profilya strel'chatoi lapy kul'tivatora metodom variatsionnogo ischisleniya // V sbornike: Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii: «Dostizheniya tekhniki i tekhnologii v APK, posvyashchennoi pamyati professora V. G. Artem'eva» – Ul'yanovsk: Ul'yanovskii GAU, 2018. – S.222–230.

7. Syromyatnikov Yu.N. Obosnovanie formy naral'nika minimal'nogo tyagovogo soprotivleniya // Sіl's'kogospodars'kі mashini. – 2018. – № 39. – S.117–132.

8. Syromyatnikov Yu.N., Voinash S.A., Nanka A.V. Naral'nik minimal'nogo tyagovogo soprotivleniya // V sbornike: Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii: «Nauka i innovatsii: vektory razvitiya» – Barnaul: RIO Altaiskogo GAU, 2018. – Kn. 2. – S.70–73.

9. Syromyatnikov Yu. N., Obosnovanie profilya rykhlitel'noi lapy metodom variatsionnogo ischesleniya // Agrotekhnika i energoobespechenie. – 2018. – № 3 (20). – S.76–84.

10. Siromyatnikov Yu. M. Vdoskonalennya robochikh organіv dlya pіdrіzannya ta pіdiomu ґruntu rozrikhlyuval'no-separuyuchoyu mashinoyu // Іnzhenerіya prirodokoristuvannya. – 2017. – №. 2 (8). – S. 74-77.

11. Nanka A.V., Syromyatnikov Yu.N. Vliyanie chastoty vrashcheniya rotora pochvoobrabatyvayushchei mashiny na kachestvennye pokazateli ee raboty // Agrotekhnika i energoobespechenie. – 2018. – № 2 (19). – S.101–116.

12. Nanka O.V., Siromyatnikov Yu.M. Vpliv chastoti obertannya rotora gruntoobrobnoї eksperimental'noї ustanovki na pokazniki yakostі // Tekhnіchnii servіs agropromislovogo, lіsovogo ta transportnogo kompleksіv. – 2019. – №. 15. – S. 96-110.

13. Usaborisut P., Prasertkan K. Performance of combined tillage tool operating under four different linkage configurations // Soil and Tillage Research. – 2018. – T. 183. – S. 109-114. DOI 10.1016/j.still.2018.06.004

14. Anpat R. M., Raheman H. Investigations on power requirement of active-passive combination tillage implement // Engineering in agriculture, environment and food. – 2017. – T. 10. – №. 1. – S. 4-13. DOI 10.1016/j.eaef.2016.06.004

15. Lobachevskii Ya.P., Starovoitov S.I., Chemisov N.N. Energeticheskaya i tekhnologicheskaya otsenka pochvoobrabatyvayushchego rabochego organa. // Sel'skokhozyaistvennye mashiny i tekhnologii. 2015;(5):10-13.

16. Mudarisov S. G., Gabitov I. I., Lobachevsky Y. P., Mazitov N. K., Rakhimov R. S., Khamaletdinov R. ,Gareev, R. T. Modeling the technological process of tillage // Soil and Tillage Research. – 2019. – T. 190. – S. 70-77. DOI 10.1016/j.still.2018.12.004

17. Kornienko S., Pashenko V., Melnik V., Kharchenko S., Khramov N. Developing the method of constructing mathematical models of soil condition under the action of a wedge // Eastern European Journal of Enterprise Technologies. Volume 5, Issue 7-83, 2016, Pages 34-43. DOI 10.15587/1729-4061.2016.79912

18. Syromyatnikov Yu.N. Rezul'taty polevykh issledovanii rotornoi pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny s eksperimental'nymi rabochimi organami. // Vestnik Altaiskogo gosudarstvennogo agrarnogo universiteta. – 2018. – № 5 (163). – S.184–193.

19. Syromyatnikov Yu.N. Rabochie organy dlya podrezaniya i pod''ema pochvy pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny // Vestnik agrarnoi nauki Dona – 2018. – № 3 (43) – S. 49-56.

20. Pashchenko V. F., Siromyatnikov Yu. M., Khramov M. S. Gruntoobrobna ustanovka z vikoristannyam gnuchkogo robochogo organu dlya kontrolyu rostu bur’yanіv // Ovochіvnitstvo і bashtannitstvo. – 2018. – № 64. – S.33–44. DOI: 10.32717/0131-0062-2018-64-33-43

21. Syromyatnikov Yu.N., Khramov N.S., Voinash S.A. Gibkii element v sostave rabochikh organov rotornoi pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny // Traktory i sel'khozmashiny. – 2018. – № 5. – S.32–40.

22. Pashchenko V.F., Syromyatnikov Yu.N. Transportiruyushchaya sposobnost' rotora pochvoobrabatyvayushchei rykhlitel'no-separiruyushchei mashiny // Traktory i sel'khozmashiny. – 2019. – № 2. – S.67–75. DOI: 10.31992/0321-4443-2019-2-67-74.

23. Syromyatnikov Yu.N. Sovershenstvovanie rabochikh organov rotora rykhlitel'no-separiruyushchei pochvoobrabatyvayushchei mashiny obespechivayushchikh minimal'nye zatraty energii na ego rabotu // Іnzhenerіya prirodokoristuvannya. – 2018. – №. 1 (9). – S. 91-95.

24. Pashchenko V.F., Nanka O.V., Siromyatnikov Yu.M. Konstruktsіya nozha rotora rozrikhlyuval'no-separuyuchogo pristroyu grunoobrobnoї mashini // Іnzhenerіya prirodokoristuvannya. – №. 1 (11). – S. 56-68.

25. Pashchenko, V., Syromyatnikov, Y., Khramov, N.. yakіsnі pokazniki roboti ґruntoobrobnoї ustanovki pri viroshchuvannі tsukrovikh buryakіv. // Ovochіvnitstvo і bashtannitstvo, – 2019. № 65, – S 39-49. DOI 10.32717/0131-0062-2019-65-39-49.

Link to this article

You can simply select and copy link from below text field.

|